Another Silent, Fanless 10 Gigabit Switch

Or, removing fans and changing air flow patterns for silence.

In our last experiment, we swapped better heatsinks and thermal paste from fans and cheap, poorly applied thermal tape for a silent, fanless 10 Gigabit Ethernet switch. Now, we've done one better.

The First Attempt

Let's quickly re-visit the first attempt. A cheap, industrial 1/10 Gbe (for gigabit ethernet) switch was modified to remove the fans and stock heatsink. The resulting high quality, individual heat sinks with better thermal paste performed better (cooler temps, 0 dB noise) in testing than the stock heatsink with fans disabled. However, this worked great so long as the switch was horizontal. Thermal paste is not thermal glue, and therefore, the heatsinks fall off at running temperature when mounted *any* orientation other than 90°. So, we needed a better solution.

Before we get started, the ambient temperature in the room is 22 ℃. This matters because really we're trying to measure the effectiveness of solutions as both total peak and degrees above ambient temperatures. Cooling effectiveness is really about degrees above ambient temperature. If the heatsink always is 20 ℃ above ambient, if it's a hot day at 30 ℃, can the solution maintain that 20 ℃ differential? Can we keep the chipsets under maximum rated temperatures under normal conditions?

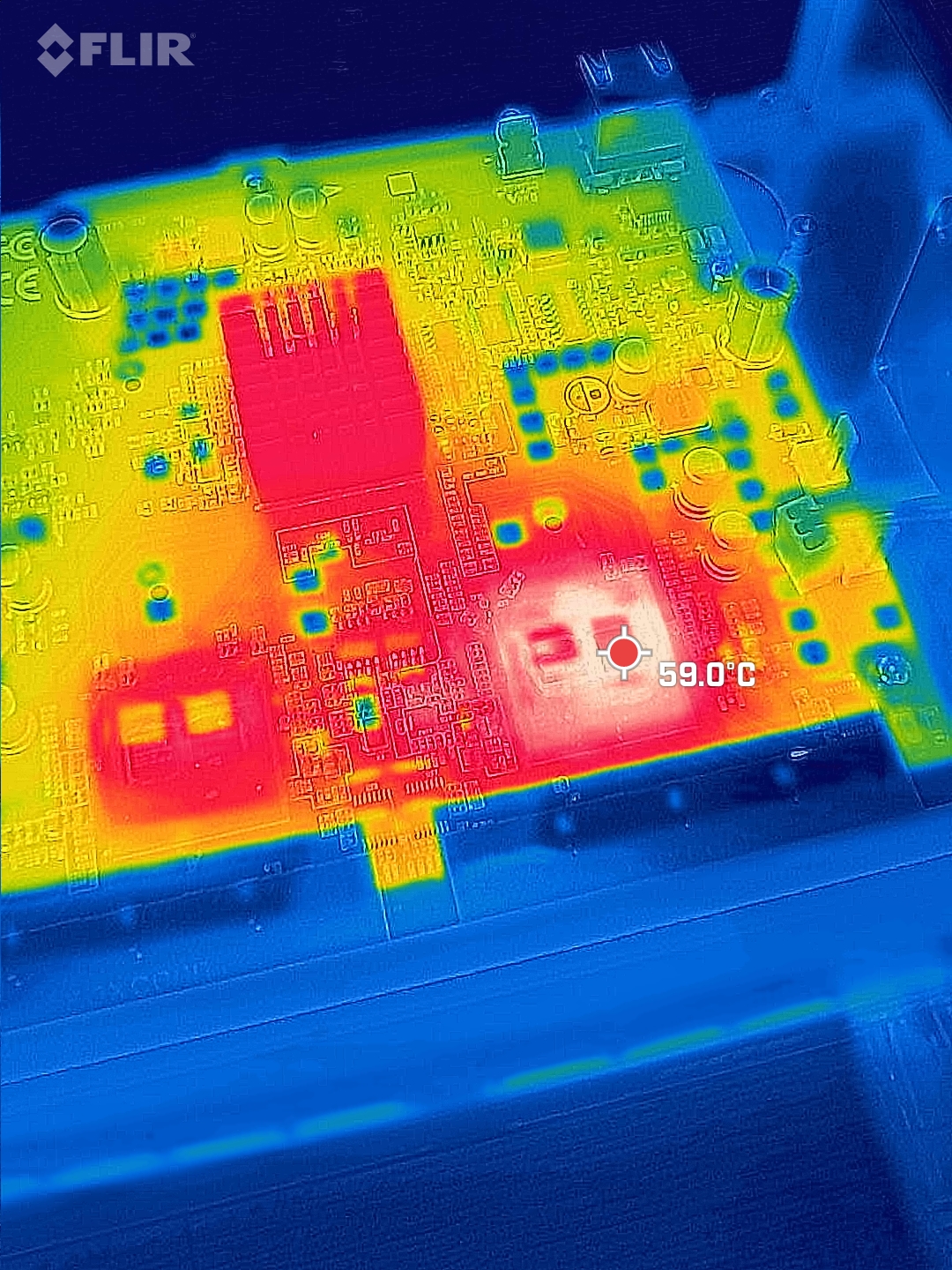

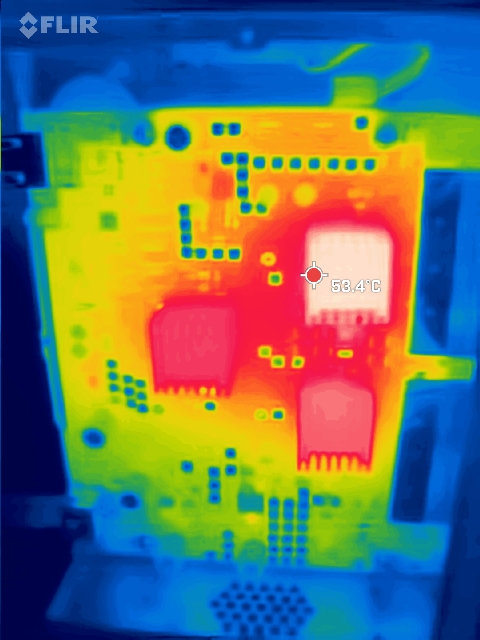

There are open grilles in the switch case on either end. Sitting on a desktop, the fans would pull the air through the right vent, across the heatsink (which also has a fan), and out the left side of the case. This maintained temperatures around 45 ℃ in normal usage. With the fans disabled, better heatsinks/thermal paste, in the same desktop position, temperatures were around 50 ℃. Mounting the switch vertically, so that the vented grilles are positioned on top/bottom of the switch (aka sideways), dropped the normal temps to 47 ℃. Slight improvement. However, the aforementioned "thermal paste is not glue" comes into play here. The heatsinks fell off the chips because the thermal paste turns into a viscous gel and slides off the chip. There's no easy way to pin the heatsinks onto the PCB without some very careful drilling around the circuits in the board. Plan B: use high temperature thermal epoxy. The heat conductivity is roughly the same, but the heatsinks no longer fall off the chips. However, the new normal operating temperature is slightly higher at 52.5 ℃. Hmm. We need either heatpipes or a better solution. In the thermal image below, you can see one of the old fan grilles on the bottom.

In this orientation, with the case off, the airflow is not optimal. Once the case is on, the closed system sets up a convection flow from bottom to top (hotter air rises). Once concern is that the top right heatsink will heat up because it has to conduct the heat from its own chipset, and handle the warmer air emitted from the bottom chipset/heatsink. I know, just use a fan! But then it's not silent. In practice, the top right heatsink does get warmer than the other two.

The top right heatsink is 53.4 ℃ with both chipsets operating at normal usage levels. Ok, can we do better?

Second Attempt

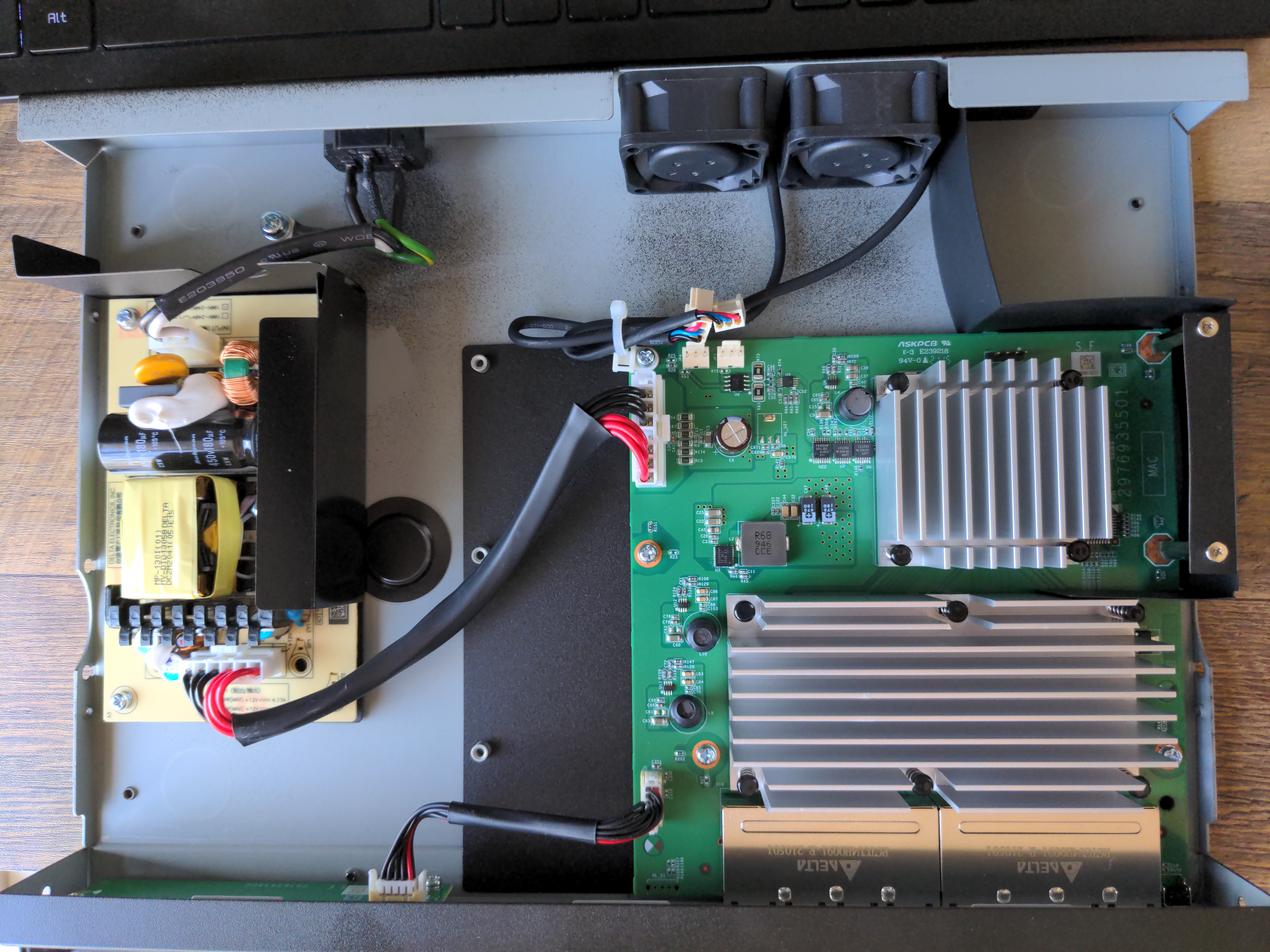

The other issue with the industrial switch is that it only supports 1 or 10 Gb connections, nothing in between. Slowly 2.5 Gb Ethernet capabilities are being added to laptops and such. I found and acquired two new switches that support 802.3an, 802.3bz and/or 802.3-2018 standards. Buffalo Technology makes a cheapish switch which supports these standards, has a metal case, and can be modified. I bought two refurbished units to replace my aging 1 Gbe infrastructure. They come with two 40x40x20mm brushless fans mounted to the case. They are loud as hell even at idle. I spent some time trying to replace the fans with Noctua silent fans, but the amperage difference is too great and it didn't work. When I opened the case to experiment with quieter fans, the first thing I noticed is how much free space there is in this switch. The second is the massive heatsinks with pushpins already in place.

There are a few things to note in the layout shown in the picture above. First is the sheer amount of empty space. Second is the plastic baffles used to direct airflow. Third is the massive heatsinks with pushpin mounts. Being lazy, what's the baseline temperature of the switch at normal operating usage without fans? Well, it turns out pretty cool at 33 ℃ (roughly). Ok, job done. Supports more speeds and runs cooler out of the box.

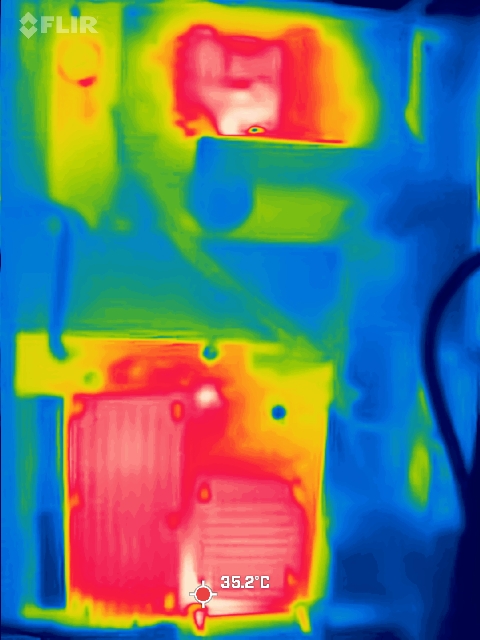

At normal operating level, the hottest part isn't the switching chipsets at all, it's a tiny controller chipset not covered by a heatsink.

The tiny controller chipset is running at 35.2 ℃. The heatsinks are around 33 ℃. Another benefit is that the vents in the case are on both sides and in the back. This orientation allows me to mount the switch vertically with the rear vents (where the fans are mounted) at the top.

Even at heavy loads where I have multiple 10 gbe devices running at nearly 10 gbs, the measured heatsink temperature is only 45 ℃. It's pretty great.

I now have 2 10 gbs switches running silent with full capabilities. Problem solved.

Next up, can I move the PCB and power supply in the case to a smaller case? Can I have an aluminum or copper block machined to cover the chipsets and make them both fully functional and a great looking desktop item? Can I disable the internal management engine and make them effectively unmanaged? Would a heatpipe assembly do better? How much better? All on my future project list.